Expert Tips for Commercial Refrigeration Repair Service to Keep Your Service Running Efficiently

Preserving the capability of commercial refrigeration systems is vital for the smooth operation of companies in the food and drink industry. From guaranteeing perishables continue to be fresh to preserving ideal temperature levels for food safety, the dependability of these devices is non-negotiable. Expert suggestions for business refrigeration repair can serve as a lifeline in browsing the intricacies of these systems, allowing services to avert interruptions and economic losses. By applying calculated upkeep practices and quickly resolving issues as they develop, businesses can secure their operations and support high quality criteria.

Routine Maintenance Practices

Regular maintenance techniques are crucial for guaranteeing the efficiency and durability of commercial refrigeration systems. By implementing a routine upkeep timetable, organizations can minimize the danger of unforeseen break downs, decrease energy intake, and lengthen the life expectancy of their refrigeration systems. One important maintenance job is regular cleansing of the condenser coils to stop dust and particles accumulation, which can impede heat transfer and bring about compressor failing. In addition, changing and examining air filters is crucial to preserving proper air movement and avoiding the system from overworking.

In addition, examining and tightening electrical connections can aid protect against electric concerns that may disrupt the system's operation. By focusing on regular upkeep practices, services can make sure that their business refrigeration systems run successfully and reliably, supporting the smooth running of their operations.

Troubleshooting Common Issues

Are you experiencing problems with your industrial refrigeration system that are influencing its efficiency? Repairing usual troubles promptly is important to ensure your company operations run smoothly.

One more common problem is excessive frost buildup in the freezer. This can be due to concerns with the defrost heating system, thermostat, or timer. Consistently thawing the device and inspecting these elements can assist avoid frost accumulation. Additionally, if you see water leakage around the unit, it can show an obstructed or frozen drain line. Clearing up the drainpipe line of any obstructions can settle this problem.

Importance of Timely Repairs

Immediately resolving concerns in a business refrigeration system is essential not only for preserving smooth organization operations but likewise for stressing the significance of timely repair services in protecting against possible disturbances. When a refrigeration system breakdowns, it can bring about substantial consequences such as food spoilage, financial losses, and even regulatory violations. Timely repairs play a vital role in preventing these negative outcomes. By promptly dealing with any kind of problems that develop, organizations can make sure that their refrigeration systems run successfully, decreasing downtime and making best use of performance.

In addition, positive upkeep and swift repair work can extend the life-span of commercial refrigeration devices, inevitably saving companies cash in the future. Normal inspections and instant fixings assist recognize and fix small troubles prior to they escalate into significant concerns that need expensive fixings or replacements. Furthermore, attending to fixings quickly can improve energy effectiveness, decreasing utility prices and promoting ecological sustainability.

Essentially, focusing on timely fixings for industrial refrigeration systems is crucial for ensuring seamless service procedures, lessening economic losses, and lengthening the life-span of tools.

Updating for Performance

Enhancing the performance of business refrigeration systems via upgrades is a critical strategy for maximizing efficiency and minimizing operational expenses. Upgrading components such as compressors, controls, evaporators, and condensers can bring about substantial power cost savings and improved overall system functionality.

One trick upgrade to take into consideration is purchasing energy-efficient compressors. These compressors are created to take in less energy while maintaining high efficiency degrees, leading to lower electrical energy expenses and reduced environmental impact. Additionally, upgrading to advanced condenser devices with variable rate drives can assist regulate temperature better, bring about boosted cooling down performance and temperature level control.

Additionally, replacing outdated evaporator coils with more recent designs can enhance heat transfer performance, ensuring that the refrigeration system runs at peak efficiency. Upgrading control systems to smart, programmable devices can also give better monitoring and policy of temperature setups, additionally enhancing power usage.

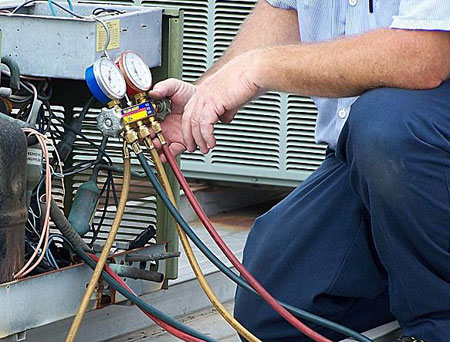

Hiring Professional Technicians

To ensure the effective application of industrial refrigeration system upgrades, it is critical to work with look at this site expert technicians with proficiency in optimizing tools efficiency and effectiveness. Expert service technicians possess the needed skills and expertise to diagnose concerns accurately, suggest appropriate options, and perform fixings effectively. When selecting service technicians for commercial refrigeration repair, think about factors such as accreditations, experience in handling various refrigeration systems, and a record of successful repair work.

Conclusion

Finally, keeping routine upkeep practices, fixing typical concerns, making certain timely fixings, upgrading for efficiency, and hiring expert specialists are crucial action in guaranteeing the smooth operation of industrial refrigeration systems. By complying with these professional pointers, organizations can avoid costly breakdowns, decrease downtime, and extend the life expectancy of their refrigeration devices. Focusing on the proper care and upkeep of business refrigeration systems is crucial for the overall success and efficiency go to website of a business.

Specialist ideas for industrial refrigeration repair can offer as a lifeline in browsing the complexities of these systems, allowing organizations to prevent interruptions and financial losses. By focusing on routine upkeep techniques, services can guarantee that their business refrigeration systems run efficiently and accurately, supporting the smooth running of their procedures.

Quickly addressing problems in a commercial refrigeration system is critical not just for maintaining smooth service operations yet also for stressing the value of prompt repair services in preventing possible disruptions. When picking service technicians for commercial refrigeration repair service, consider aspects such as certifications, experience in managing numerous refrigeration systems, and a track document of effective repairs.

In final thought, keeping normal maintenance practices, troubleshooting typical problems, making sure prompt repairs, upgrading for efficiency, and hiring professional technicians are essential steps in guaranteeing the smooth operation of commercial refrigeration systems.